refractory

material not deformed or damaged by high temperatures, used to make crucibles, incinerators, insulation, and furnaces, particularly metallurgical furnaces. Refractories are produced in several forms: molded bricks of various shapes (see firebrick); bulk granular materials; plastic mixtures consisting of moistened aggregate that are rammed into place; castables composed of dry aggregates and a binder that can be mixed with water and poured like concrete; and mortars and cements for laying brickwork.

Refractories may be chemically acid, basic, or neutral, depending on the application. Silica (made from sand or quartzite), zircon (for extreme heat resistance), and fireclay (made by baking kaolin) are acid; magnesite and dolomite are alkaline; high-alumina refractories, mullite, chromite, silicon carbide, and carbon are neutral. Carbon is an excellent refractory in places where no oxygen can contact it, as in the hearth of a blast furnace. A smelting-furnace lining must be acid if the slag is acid and basic if the slag is basic, so that it will not react and be eroded.

Magnesite and dolomite are the most important refractory materials; their oxides are used in open-hearth steel furnaces and in portland-cement kilns. In fact, most refractories are oxides; others include silica, alumina, chromite, and zirconia. Fireclay is a mixture of silica and alumina, with impurities that soften the bricks at high temperatures. Silicon carbide (not an oxide) has a high strength at elevated temperatures, but both silicon and carbon burn in oxidizing atmospheres if the protective skin of silica flakes off. The ideal refractory material has a high compressive strength at furnace temperatures, a low thermal conductivity, and a low coefficient of expansion. Refractory insulating bricks approach this ideal.

Special types of refractories are required in nuclear power plants. Various materials that have outstanding chemical and physical stability at high temperatures have been tested and adopted. They include high-melting oxides, carbides, sulfides, and nitrides, none of which has been widely employed as refractories.

industrial material

Introduction

any material that has an unusually high melting point and that maintains its structural properties at very high temperatures. Composed principally of ceramics, refractories are employed in great quantities in the metallurgical, glassmaking, and ceramics industries, where they are formed into a variety of shapes to line the interiors of furnaces, kilns, and other devices that process materials at high temperatures.

In this article the essential properties of ceramic refractories are reviewed, as are the principal refractory materials and their applications. At certain points in the article reference is made to the processing techniques employed in the manufacture of ceramic refractories; more detailed description of these processes can be found in the articles traditional ceramics and advanced ceramics. The connection between the properties of ceramic refractories and their chemistry and microstructure is explained in ceramic composition and properties.

Properties

Because of the high strengths exhibited by their primary chemical bonds, many ceramics possess unusually good combinations of high melting point and chemical inertness. This makes them useful as refractories. (The word refractory comes from the French réfractaire, meaning “high-melting.”) The property of chemical inertness is of special importance in metallurgy and glassmaking, where the furnaces are exposed to extremely corrosive molten materials and gases. In addition to temperature and corrosion resistance, refractories must possess superior physical wear or abrasion resistance, and they also must be resistant to thermal shock. Thermal shock occurs when an object is rapidly cooled from high temperature. The surface layers contract against the inner layers, leading to the development of tensile stress and the propagation of cracks. Ceramics, in spite of their well-known brittleness, can be made resistant to thermal shock by adjusting their microstructure during processing. The microstructure of ceramic refractories is quite coarse when compared with whitewares such as porcelain or even with less finely textured structural clay products such as brick. The size of filler grains can be on the scale of millimetres, instead of the micrometre scale seen in whiteware ceramics. In addition, most ceramic refractory products are quite porous, with large amounts of air spaces of varying size incorporated into the material. The presence of large grains and pores can reduce the load-bearing strength of the product, but it also can blunt cracks and thereby reduce susceptibility to thermal shock. However, in cases where a refractory will come into contact with corrosive substances (for example, in glass-melting furnaces), a porous structure is undesirable. The ceramic material can then be made with a higher density, incorporating smaller amounts of pores.

Composition and processing

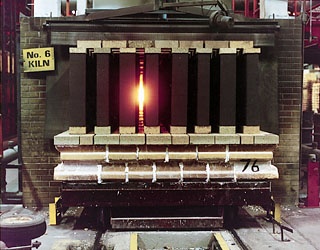

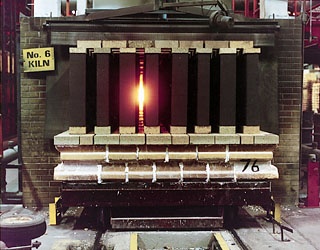

The composition and processing of ceramic refractories vary widely according to the application and the type of refractory. Most refractories can be classified on the basis of composition as either clay-based or nonclay-based. In addition, they can be classified as either acidic (containing silica 【SiO2】 or zirconia 【ZrO2】) or basic (containing alumina 【Al2O3】 or alkaline-earth oxides such as lime 【CaO】 or magnesia 【MgO】). Among the clay-based refractories are fireclay, high-alumina, and mullite ceramics. There is a wide range of nonclay refractories, including basic, extra-high alumina, silica, silicon carbide, and zircon materials. Most clay-based products are processed in a manner similar to other traditional ceramics such as structural clay products; e.g., stiff-mud processes such as press forming or extrusion are employed to form the ware, which is subsequently dried and passed through long tunnel kilns for firing (see Figure 1-->

The composition and processing of ceramic refractories vary widely according to the application and the type of refractory. Most refractories can be classified on the basis of composition as either clay-based or nonclay-based. In addition, they can be classified as either acidic (containing silica 【SiO2】 or zirconia 【ZrO2】) or basic (containing alumina 【Al2O3】 or alkaline-earth oxides such as lime 【CaO】 or magnesia 【MgO】). Among the clay-based refractories are fireclay, high-alumina, and mullite ceramics. There is a wide range of nonclay refractories, including basic, extra-high alumina, silica, silicon carbide, and zircon materials. Most clay-based products are processed in a manner similar to other traditional ceramics such as structural clay products; e.g., stiff-mud processes such as press forming or extrusion are employed to form the ware, which is subsequently dried and passed through long tunnel kilns for firing (see Figure 1--> ). Firing, as described in the article traditional ceramics, induces partial vitrification, or glass formation, which is a liquid-sintering process that binds particles together. Nonclay-based refractories, on the other hand, are bonded using techniques reserved for advanced ceramic materials. For instance, extra-high alumina and zircon ceramics are bonded by transient-liquid or solid-state sintering, basic bricks are bonded by chemical reactions between constituents, and silicon carbide is reaction-bonded from silica sand and coke. These processes are described in the article advanced ceramics.

). Firing, as described in the article traditional ceramics, induces partial vitrification, or glass formation, which is a liquid-sintering process that binds particles together. Nonclay-based refractories, on the other hand, are bonded using techniques reserved for advanced ceramic materials. For instance, extra-high alumina and zircon ceramics are bonded by transient-liquid or solid-state sintering, basic bricks are bonded by chemical reactions between constituents, and silicon carbide is reaction-bonded from silica sand and coke. These processes are described in the article advanced ceramics.Clay-based refractories

In this section the composition and properties of the clay-based refractories are described. Most are produced as preformed brick. Much of the remaining products are so-called monolithics, materials that can be formed and solidified on-site. This category includes mortars for cementing bricks and mixes for ramming or gunning (spraying from a pressure gun) into place. In addition, lightweight refractory insulation can be made in the form of fibreboards, blankets, and vacuum-cast shapes.

Fireclay

The workhorse of the clay-based refractories are the so-called fireclay materials. These are made from clays containing the aluminosilicate mineral kaolinite (Al2【Si2O5】【OH】4) plus impurities such as alkalis and iron oxides. The alumina content ranges from 25 to 45 percent. Depending upon the impurity content and the alumina-to-silica ratio, fireclays are classified as low-duty, medium-duty, high-duty, and super-duty, with use temperature rising as alumina content increases. Fireclay bricks, or firebricks (firebrick), exhibit relatively low expansion upon heating and are therefore moderately resistant against thermal shock. They are fairly inert in acidic environments but are quite reactive in basic environments. Fireclay bricks are used to line portions of the interiors of blast furnaces, blast-furnace stoves, and coke ovens.

High alumina

High-alumina refractories are made from bauxite, a naturally occurring material containing aluminum hydroxide (Al【OH】3) and kaolinitic clays. These raw materials are roasted to produce a mixture of synthetic alumina and mullite (an aluminosilicate mineral with the chemical formula 3Al2O3 · 2SiO2). By definition high-alumina refractories contain between 50 and 87.5 percent alumina. They are much more robust than fireclay refractories at high temperatures and in basic environments. In addition, they exhibit better volume stability and abrasion resistance. High-alumina bricks are used in blast furnaces, blast-furnace stoves, and liquid-steel ladles.

Mullite

Mullite is an aluminosilicate compound with the specific formula 3Al2O3 · 2SiO3 and an alumina content of approximately 70 percent. It has a melting point of 1,850° C (3,360° F). Various clays are mixed with bauxite in order to achieve this composition. Mullite refractories are solidified by sintering in electric furnaces at high temperatures. They are the most stable of the aluminosilicate refractories and have excellent resistance to high-temperature loading. Mullite bricks are used in blast-furnace stoves and in the forehearth roofs of glass-melting furnaces.

Non-clay-based refractories

Nonclay refractories such as those described below are produced almost exclusively as bricks and pressed shapes, though some magnesite-chrome and alumina materials are fuse-cast into molds. The usual starting materials for these products are carbonates or oxides of metals such as magnesium, aluminum, and zirconium.

Basic

Basic refractories include magnesia, dolomite, chrome, and combinations of these materials. Magnesia brick is made from periclase, the mineral form of magnesia (MgO). Periclase is produced from magnesite (a magnesium carbonate, MgCO3), or it is produced from magnesium hydroxide (Mg【OH】2), which in turn is derived from seawater or underground brine solutions. Magnesia bricks can be chemically bonded, pitch-bonded, burned, or burned and then pitch-impregnated.

Dolomite refractories take their name from the dolomite ore, a combination of calcium and magnesium carbonates (CaCO3 · MgCO3), from which they are produced. After burning they must be impregnated with tar or pitch to prevent rehydration of lime (CaO). Chrome brick is made from chromium ores, which are complex solid solutions of the spinel type (a series of oxide minerals including chromite and magnetite) plus silicate gangue, or impurity phases.

All the basic refractories exhibit outstanding resistance to iron oxides and the basic slags associated with steelmaking—especially when they incorporate carbon additions either as flakes or as residual carbon from pitch-bonding or tar-impregnation. For this reason they find wide employment in the linings of basic oxygen furnaces, electric furnaces, and open-hearth furnaces. They also are used to line the insides of copper converters.

Extra-high alumina

Extra-high alumina refractories are classified as having between 87.5 and 100 percent Al2O3 content. The alumina grains are fused or densely sintered together to obtain high density. Extra-high alumina refractories exhibit excellent volume stability to over 1,800° C (3,275° F).

silica

Silica refractories are made from quartzites and silica gravel deposits with low alumina and alkali contents. They are chemically bonded with 3–3.5 percent lime. Silica refractories have good load resistance at high temperatures, are abrasion-resistant, and are particularly suited to containing acidic slags. Of the various grades—coke-oven quality, conventional, and super-duty—the super-duty, which has particularly low impurity contents, is used in the superstructures of glass-melting furnaces.

zircon

Refractories made of zircon (a zirconium silicate, ZrSiO4) also are used in glass tanks because of their good resistance to the corrosive action of molten glasses. They possess good volume stability for extended periods at elevated temperatures, and they also show good creep resistance (i.e., low deformation under hot loading).

silicon carbide

Silicon carbide (SiC) ceramics are made by a process referred to as reaction bonding, invented by the American Edward G. Acheson in 1891. In the Acheson process, pure silica sand and finely divided carbon (coke) are reacted in an electric furnace at temperatures in the range of 2,200°–2,480° C (4,000°–4,500° F). SiC ceramics have outstanding high-temperature load-bearing strength and dimensional stability. They also exhibit great thermal shock resistance because of their high thermal conductivity. (In this case, high thermal conductivity prevents the formation of extreme temperature differences between inner and outer layers of a material, which frequently are a source of thermal expansion stresses.) Therefore, SiC makes good kiln furniture for supporting other ceramics during their firing.

Other non-clay-based refractories

Other refractories produced in smaller quantities for special applications include graphite (a layered, multicrystalline form of carbon), zirconia (ZrO2), forsterite (Mg2SiO4), and combinations such as magnesia-alumina, magnesite-chrome, chrome-alumina, and alumina-zirconia-silica. Alumina-zirconia-silica (AZS), melted and cast directly into the melting tanks of glass furnaces, is an excellent corrosion-resistant refractory that does not release impurities into the glass melt.

Additional Reading

Useful resources on refractories include Harbison-Walker Refractories, Modern Refractory Practice, 5th ed. (1992); and Refractories: Significance, History, Classifications, Manufacturing Processes, Forms, Applications, Future (1987), published by the Refractories Institute. A good introduction to ceramics in general is provided by David W. Richerson, Modern Ceramic Engineering: Properties, Processing, and Use in Design, 2nd ed., rev. and expanded (1992). The processing of traditional ceramics is described in F.H. Norton, Elements of Ceramics, 2nd ed. (1974); James S. Reed, Introduction to the Principles of Ceramic Processing (1988); George Y. Onoda, Jr., and Larry L. Hench, Ceramic Processing Before Firing (1978); and four sections of Theodore J. Reinhart (ed.), Engineered Materials Handbook, vol. 4, Ceramics and Glasses, ed. by Samuel J. Schneider (1991): “Ceramic Powders and Processing,” pp. 41–122; “Forming and Predensification, and Nontraditional Densification Processes,” pp. 123–241; “Firing/Sintering: Densification,” pp. 242–312; and “Final Shaping and Surface Finishing,” pp. 313–376.

- Huey P. Newton

- Huey Smith

- Hu Feng

- Huffington Post, The

- Hufūf, Al-

- Hugenberg, Alfred

- Huggins, Charles B.

- Huggins, Sir William

- Hugh, Baron Dacre of Glanton Trevor-Roper

- Hugh Boulter

- Hugh Burgess

- Hugh Capet

- Hugh Caswall Tremenheere Dowding, 1st Baron Dowding

- Hugh Caswall Tremenheere Dowding Dowding, 1st Baron

- Hugh Chamberlen, The Elder

- Hugh Chisholm

- Hugh Cholmondeley, 3rd Baron Delamere

- Hugh Cholmondeley Delamere, 3rd Baron

- Hugh Clapperton

- Hugh Culling Eardley Childers

- Hugh de Lacy, 1st Lord of Meath

- Hugh de Lacy, earl of Ulster

- Hugh de Lacy Meath, 1st Lord of

- Hugh de Lacy Ulster, earl of

- Hugh Emrys Griffith