slider-crank mechanism

mechanics

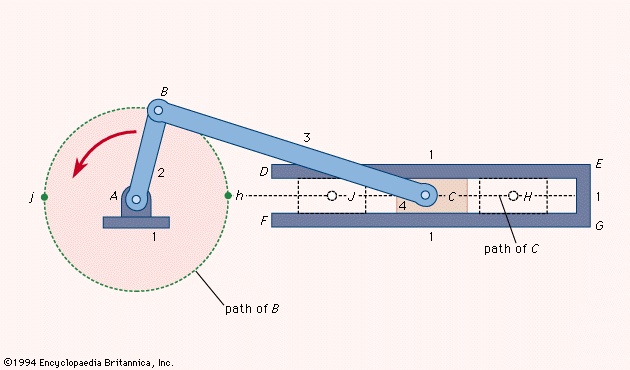

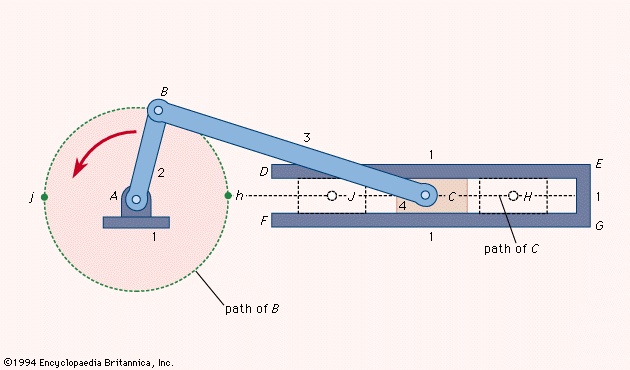

arrangement of mechanical parts designed to convert straight-line motion to rotary motion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump. The basic nature of the mechanism and the relative motion of the parts can best be described with the aid of the accompanying figure-->

arrangement of mechanical parts designed to convert straight-line motion to rotary motion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump. The basic nature of the mechanism and the relative motion of the parts can best be described with the aid of the accompanying figure--> , in which the moving parts are lightly shaded. The darkly shaded part 1, the fixed frame or block of the pump or engine, contains a cylinder, depicted in cross section by its walls DE and FG, in which the piston, part 4, slides back and forth. The small circle at A represents the main crankshaft bearing, which is also in part 1. The crankshaft, part 2, is shown as a straight member extending from the main bearing at A to the crankpin bearing at B, which connects it to the connecting rod, part 3. The connecting rod is shown as a straight member extending from the crankpin bearing at B to the wristpin bearing at C, which connects it to the piston, part 4, which is shown as a rectangle. The three bearings shown as circles at A, B, and C permit the connected members to rotate freely with respect to one another. The path of B is a circle of radius AB; when B is at point h the piston will be in position H, and when B is at point j the piston will be in position J. On a gasoline engine, the head end of the cylinder (where the explosion of the gasoline-air mixture takes place) is at EG; the pressure produced by the explosion will push the piston from position H to position J; return motion from J to H will require the rotational energy of a flywheel attached to the crankshaft and rotating about a bearing collinear with bearing A. On a reciprocating piston pump the crankshaft would be driven by a motor.

, in which the moving parts are lightly shaded. The darkly shaded part 1, the fixed frame or block of the pump or engine, contains a cylinder, depicted in cross section by its walls DE and FG, in which the piston, part 4, slides back and forth. The small circle at A represents the main crankshaft bearing, which is also in part 1. The crankshaft, part 2, is shown as a straight member extending from the main bearing at A to the crankpin bearing at B, which connects it to the connecting rod, part 3. The connecting rod is shown as a straight member extending from the crankpin bearing at B to the wristpin bearing at C, which connects it to the piston, part 4, which is shown as a rectangle. The three bearings shown as circles at A, B, and C permit the connected members to rotate freely with respect to one another. The path of B is a circle of radius AB; when B is at point h the piston will be in position H, and when B is at point j the piston will be in position J. On a gasoline engine, the head end of the cylinder (where the explosion of the gasoline-air mixture takes place) is at EG; the pressure produced by the explosion will push the piston from position H to position J; return motion from J to H will require the rotational energy of a flywheel attached to the crankshaft and rotating about a bearing collinear with bearing A. On a reciprocating piston pump the crankshaft would be driven by a motor.- Lydd

- Lydgate, John

- Lydia

- Lydia Barrington Darragh

- Lydia Cabrera

- Lydia E. Pinkham

- Lydia Folger Fowler

- Lydia Maria Adams DeWitt

- Lydia Maria Child

- Lydia Moss Bradley

- Lydian language

- Lydian mode

- lye

- Lyell, Mount

- Lyell, Sir Charles, Baronet

- lygaeid bug

- Lyly, John

- Lyman Abbott

- Lyman Beecher

- Lyman, Jr. Spitzer

- Lyman (Louis) Lemnitzer

- Lyman Reed Blake

- Lyman Spitzer, Jr.

- Lyman Trumbull

- Lyme disease