turbine

Introduction

any of various devices that convert the energy in a stream of fluid into mechanical energy. The conversion is generally accomplished by passing the fluid through a system of stationary passages or vanes that alternate with passages consisting of finlike blades attached to a rotor. By arranging the flow so that a tangential force, or torque, is exerted on the rotor blades, the rotor turns, and work is extracted.

Turbines can be classified into four general types according to the fluids used: water, steam, gas, and wind. Although the same principles apply to all turbines, their specific designs differ sufficiently to merit separate descriptions.

A water turbine uses the potential energy resulting from the difference in elevation between an upstream water reservoir and the turbine-exit water level (the tailrace) to convert this so-called head into work. Water turbines are the modern successors of simple waterwheels, which date back about 2,000 years. Today, the primary use of water turbines is for electric power generation.

The greatest amount of electrical energy comes, however, from steam turbines coupled to electric generators. The turbines are driven by steam produced in either a fossil-fuel-fired or a nuclear-powered generator. The energy that can be extracted from the steam is conveniently expressed in terms of the enthalpy change across the turbine. Enthalpy reflects both thermal and mechanical energy forms in a flow process and is given by the sum of the internal thermal energy and the product of pressure times volume. The available enthalpy change through a steam turbine increases with the temperature and pressure of the steam generator and with reduced turbine-exit pressure.

For gas turbines, the energy extracted from the fluid also can be expressed in terms of the enthalpy change, which for a gas is nearly proportional to the temperature drop across the turbine. In gas turbines the working fluid is air mixed with the gaseous products of combustion. Most gas-turbine engines include at least a compressor, a combustion chamber, and a turbine. These are usually mounted as an integral unit and operate as a complete prime mover on a so-called open cycle where air is drawn in from the atmosphere and the products of combustion are finally discharged again to the atmosphere. Since successful operation depends on the integration of all components, it is important to consider the whole device, which is actually an internal-combustion engine, rather than the turbine alone. For this reason, gas turbines are treated in the article internal-combustion engine.

The energy available in wind can be extracted by a wind turbine to produce electric power or to pump water from wells. Wind turbines are the successors of windmills, which were important sources of power from the late Middle Ages through the 19th century.

Water turbines

Water turbines are generally divided into two categories: (1) impulse turbines used for high heads of water and low flow rates and (2) reaction turbines normally employed for heads below about 450 metres and moderate or high flow rates. These two classes include the main types in common use—namely, the Pelton impulse turbine and the reaction turbines of the Francis, propeller, Kaplan, and Deriaz variety. Turbines can be arranged with either horizontal or, more commonly, vertical shafts. Wide design variations are possible within each type to meet the specific local hydraulic conditions. Today, most hydraulic turbines are used for generating electricity in hydroelectric installations.

Impulse turbines

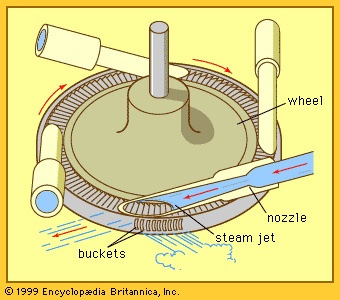

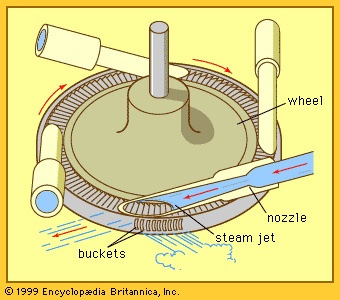

In an impulse turbine the potential energy, or the head of water, is first converted into kinetic energy by discharging water through a carefully shaped nozzle. The jet, discharged into air, is directed onto curved buckets fixed on the periphery of the runner to extract the water energy and convert it to useful work.

Modern impulse turbines are based on a design patented in 1889 by the American engineer Lester Allen Pelton. The free water jet strikes the turbine buckets tangentially. Each bucket has a high centre ridge so that the flow is divided to leave the runner at both sides. Pelton wheels are suitable for high heads, typically above about 450 metres with relatively low water flow rates. For maximum efficiency the runner tip speed should equal about one-half the striking jet velocity. The efficiency (work produced by the turbine divided by the kinetic energy of the free jet) can exceed 91 percent when operating at 60–80 percent of full load.

The power of a given wheel can be increased by using more than one jet. Two-jet arrangements are common for horizontal shafts. Sometimes two separate runners are mounted on one shaft driving a single electric generator. Vertical-shaft units may have four or more separate jets.

If the electric load on the turbine changes, its power output must be rapidly adjusted to match the demand. This requires a change in the water flow rate to keep the generator speed constant. The flow rate through each nozzle is controlled by a centrally located, carefully shaped spear or needle that slides forward or backward as controlled by a hydraulic servomotor.

Proper needle design assures that the velocity of the water leaving the nozzle remains essentially the same irrespective of the opening, assuring nearly constant efficiencies over much of the operating range. It is not prudent to reduce the water flow suddenly to match a load decrease. This could lead to a destructive pressure surge (water hammer) in the supply pipeline, or penstock. Such surges can be avoided by adding a temporary spill nozzle that opens while the main nozzle closes or, more commonly, by partially inserting a deflector plate between the jet and the wheel, diverting and dissipating some of the energy while the needle is slowly closed.

Another type of impulse turbine is the turgo type. The jet impinges at an oblique angle on the runner from one side and continues in a single path, discharging at the other side of the runner. This type of turbine has been used in medium-sized units for moderately high heads.

Reaction turbines

In a reaction turbine, forces driving the rotor are achieved by the reaction of an accelerating water flow in the runner while the pressure drops. The reaction principle can be observed in a rotary lawn sprinkler where the emerging jet drives the rotor in the opposite direction. Due to the great variety of possible runner designs, reaction turbines can be used over a much larger range of heads and flow rates than impulse turbines. Reaction turbines typically have a spiral inlet casing that includes control gates to regulate the water flow. In the inlet a fraction of the potential energy of the water may be converted to kinetic energy as the flow accelerates. The water energy is subsequently extracted in the rotor.

There are, as noted above, four major kinds of reaction turbines in wide use: the Kaplan, Francis, Deriaz, and propeller type. In fixed-blade propeller and adjustable-blade Kaplan turbines (named after the Austrian inventor Victor Kaplan), there is essentially an axial flow through the machine. The Francis- and Deriaz-type turbines (after the British-born American inventor James B. Francis and the Swiss engineer Paul Deriaz, respectively) use a “mixed flow,” where the water enters radially inward and discharges axially. Runner blades on Francis and propeller turbines consist of fixed blading, while in Kaplan and Deriaz turbines the blades can be rotated about their axis, which is at right angles to the main shaft.

Axial-flow machines

Fixed propeller-type turbines are generally used for large units at low heads, resulting in large diameters and slow rotational speeds. As the name suggests, a propeller-type turbine runner looks like the very large propeller of a ship except that it serves the opposite purpose: power is extracted in a turbine, whereas it is fed into a marine propeller. The central shaft, or hub, may have the propeller blades bolted to it during on-site assembly, thus permitting shipment by sections for a large runner. At low heads (below about 24 metres), vertical-shaft propeller turbines typically have a concrete spiral inlet casing of rectangular cross section. Inlet guide vanes are either mounted on a ring or, in large units, set individually directly into the concrete. The flow passage can be increased or decreased by servomotor-driven wicket gates. The kinetic energy leaving the runner can be partially recaptured by a draft tube, a conical diffusing exit section where the velocity is decreased while the pressure is increased. This leads to improved efficiency by keeping the loss of kinetic energy in the exit, or tail, section of the installation to a minimum.

Propeller turbines are used extensively in North America, where low heads and large flow rates are common. For example, there are 32 propeller turbines in the Moses–Saunders Power Dam on the St. Lawrence River between New York and Ontario—16 operated by the United States and 16 by Canada, with each turbine rated at 50,000 kilowatts. With such large plants it is possible to run each turbine at or near its most efficient output by switching complete units in or out as the load fluctuates, in addition to regulating each unit.

If the head or the water flow rate tends to vary seasonally, as occurs in many river systems, an installation with only a few propeller turbines might have to operate all units at partial output under average flow and load conditions. The energy-conversion efficiency of a conventional propeller turbine decreases rapidly once the turbine load drops below 75 percent of its rating. This performance loss can be minimized by varying the inlet-blade angle of the runner to match the runner-inlet conditions more accurately with the water velocity for a given flow. In such a Kaplan turbine each blade can be swiveled about a post at right angles to the main turbine shaft, thus producing a variable pitch. The angle of the blades is controlled by an oil-pressure operated servomotor, usually mounted in the rotor hub with the oil fed through the generator and turbine shaft. The servo-control system, which also drives the gates through a cam or rocker arrangement, is designed to adjust angles and inlet flows to match the electrical load while keeping the main shaft with its directly coupled generator rotating at constant speed. Runners with four to six blades are common, though more blades may be used for high heads. British manufacturers have developed Kaplan designs for heads up to 58 metres.

Although the usual turbine installation has a vertical shaft, some also have been designed with horizontal shafts. In a horizontal bulb arrangement, the generator is embedded in a nacelle, corresponding to the thick body of a light bulb, while the blades are set around a hub corresponding to the thinner bulb socket. This design is suitable for medium-sized machines operating at very low heads when an almost straight-through water flow is desirable. The Rance River tidal plant in France employs this kind of arrangement (see Tidal plants (turbine) below).

Mixed-flow turbines

Francis turbines are probably used most extensively because of their wider range of suitable heads, characteristically from three to 600 metres. At the high-head range, the flow rate and the output must be large; otherwise the runner becomes too small for reasonable fabrication. At the low-head end, propeller turbines are usually more efficient unless the power output is also small. Francis turbines reign supreme in the medium-head range of 120 to 300 metres and come in a wide range of designs and sizes. They can have either horizontal or vertical shafts, the latter being used for machines with diameters of about two metres or more. Vertical-shaft machines usually occupy less space than horizontal units, permit greater submergence of the runner with a minimum of deep excavation, and make the tip-mounted generator more easily accessible for maintenance. Horizontal-shaft units are more compact for smaller sizes and allow easier access to the turbine, although removal of the generator for repair becomes more difficult as size increases.

The most common form of Francis turbine has a welded, or cast-steel, spiral casing. The casing distributes water evenly to all inlet gates; up to 24 pivoted gates or guide vanes have been used. The gates operate from fully closed to wide open, depending on the power output desired. Most are driven by a common regulating speed ring and are pin-connected in such a fashion that no damage will occur if debris blocks one of the gate passages. The regulating ring is rotated by one or two oil-pressure servomotors that are controlled by the speed governor.

Slow, high-power units have a nearly radial set of blades, while in fast and lower-powered units the curved blades reach from the radial inlet to almost the axial outlet. Once the overall blade dimensions (inlet and exit diameters and blade height) have been defined, the blades are designed for a smooth entry of the water flow at the inlet and minimum water swirl at the exit. The number of blades can vary from seven to 19. Runners for low-head units are usually made of cast mild steel, sometimes with stainless-steel (stainless steel) protection added at locations subject to cavitation (see below). All stainless-steel construction is more commonly used for high heads. Large units can be welded together on-site, using an appropriate combination of various preformed steel sections to provide carefully shaped, finished water passages. Francis turbines allow for very large, high-output units. The Grand Coulee (Grand Coulee Dam) hydroelectric power plant on the Columbia River in Washington state has the largest single runner in the United States, a device capable of producing 716,000 kilowatts at a head of 93 metres. The world's largest hydroelectric power installation, the Itaipú (Itaipú Dam) plant on the Paraná River between Brazil and Paraguay, is scheduled to have 18 Francis turbines capable of producing 740,000 kilowatts each at heads between 118.4 and 126.7 metres while rotating at slightly above 90 revolutions per minute (rpm).

A mixed-flow turbine of the Deriaz type uses swiveled, variable-pitch runner blades that allow for improved efficiency at part loads in medium-sized machines. The Deriaz design has proved useful for higher heads and also for some pumped storage applications (see below). It has the advantage of a lower runaway (sudden loss of load) speed than a Kaplan turbine, which results in significant savings in generator costs. Very few Deriaz turbines, however, have actually been built. The first non-reversible Deriaz turbine, capable of producing 22,750 kilowatts with a head of 55 metres, was installed in an underground station at Culligran, Scot., in 1958.

Other design considerations

Output and speed control

If the load on the generator is decreased, a turbine will tend to speed up unless the flow rate can be reduced accordingly. Similarly, an increase of load will cause the turbine to slow down unless more water can be admitted. Since electric-generator speeds must be kept constant to a high degree of precision, this leads to complex controls. These must take into account the large masses and inertias of the metal and the flowing water, including the water in the inflow pipes (or penstocks), that will be affected by any change in the wicket gate setting. If the inlet pipeline is long, the closing time of the wicket gate must be slow enough to keep the pressure increase caused by a reduction in flow velocity within acceptable limits. If the closing or opening rate is too slow, control instabilities may result. To assist regulation with long pipelines, a surge chamber is often connected to the pipeline as close to the turbine as possible. This enables part of the water in the line to pass into the surge chamber when the wicket gates are rapidly closed or opened. Medium-sized reaction turbines may also be provided with pressure-relief valves through which some water can be bypassed automatically as the governor starts to close the turbine. In some applications, both relief valves and surge chambers have been used.

cavitation

According to Bernoulli's principle (derived by the Swiss mathematician Daniel Bernoulli), as the flow velocity of the water increases at any given elevation, the pressure will drop. There is a danger that in high-velocity sections of a reaction turbine, especially near the exit, the pressure can become so low that the water flashes over into small vapour bubbles, which then collapse suddenly. This so-called cavitation leads to erosion pitting as well as to vibrations and must be avoided by the careful shaping of all blade passages and of the exit passage or draft tube.

Turbine selection on the basis of specific speed

Initial turbine selection is usually based on the ratio of design variables known as the power specific speed. In U.S. design practice this is given by

where n is in revolutions per minute, P is the output in horsepower, and H is the head of water in feet. Turbine types can be classified by their specific speed, N, which always applies at the point of maximum efficiency. If N ranges from one to 20, corresponding to high heads and low rotational speeds, impulse turbines are appropriate. For N between 10 and 90, Francis-type runners should be selected, with slow-running, near-radial units for the lower N values and more rapidly rotating mixed-flow runners for higher N values. For N up to 110, Deriaz turbines may be suitable. If N ranges from 70 to the maximum of 260, propeller or Kaplan turbines are called for.

Using the specific speed formula, a turbine designed to deliver 100,000 horsepower (74,600 kilowatts) with a head of 40 feet (12.2 metres) operating at 72 revolutions per minute would have a specific speed of 226, suggesting a propeller or Kaplan turbine. It can also be shown that the flow rate would have to be about 24,500 cubic feet per second (694 cubic metres per second) at a turbine efficiency of 90 percent. The runner diameter will be about 33 feet (10 metres). This illustrates the large sizes required for high-power, low-head installations and the low rotational speed at which these turbines have to operate to stay within the permissible specific speed range.

Turbine model testing

Before building large-scale installations, the design should be checked out with turbine model tests, using geometrically similar models of small and intermediate size, all operating at the same specific speed. Allowances must be made for the effects of friction, determined by the Reynolds number (density × rotational speed × runner diameter squared/viscosity) and for possible changes in scaled roughness and clearance dimensions. Friction effects are less important for large units, which tend to be more efficient than smaller ones.

Applications

Electric power generation

Water turbines are used almost exclusively for generating electric power (hydroelectric power) that can be transmitted through high-voltage power lines to population centres. The United States and Canada are among the leaders in hydroelectric power production, though many other countries also have major production facilities. Until the late 1950s most single turbogenerator units had capacities of less than 150,000 kilowatts. By the late 1980s construction costs and the need for reliability pointed toward 250,000- to 300,000-kilowatt units, although some recent installations were equipped with turbines capable of up to 750,000 kilowatts.

Pumped storage

Electricity must be used as soon as it is generated; there are no economical means of storing large quantities of electric energy. Thus hydroelectric plants built for near-maximum power consumption during daytime peak hours would have to operate at low efficiency during nighttime or weekend off-hours. To avoid this, water can be pumped to a second, higher reservoir during off-hours for storage in the form of potential energy and then fed back through power-generating turbines at times of high demand. Even though this system does not generate new energy (there actually is a reduction in energy due to losses involved in pump and turbine operation as well as in the electric motor and generator), pumped hydro-storage often becomes economical when compared with the cost of constructing additional turbines for peak power demands.

Modern pumped storage units in the United States normally use reversible-pump turbines that can be run in one direction as pumps and in the other direction as turbines. These are coupled to reversible electric motor/generators. The motor drives the pump during the storage portion of the cycle, while the generator produces electricity during discharge from the upper reservoir.

Most reversible-pump turbines are of the Francis type. The complexity of the unit, however, increases significantly as compared to a turbine alone. In spite of the higher costs for both hydraulic and electrical controls and support equipment, the total installed cost will be less than for completely separate pump-motor and turbine-generator assemblies with dual water passages.

Some very economical pumped storage plants have heads exceeding 300 metres. In the past this was considered too high for single-stage pumps, and the use of separate multistage, nonreversible units was required. Satisfactory reversible single-stage pump turbines, however, have been developed that can operate at 700-metre heads, though most installations have smaller head differences between the upper and lower reservoirs.

For medium heads, Deriaz turbines have had some success because they allow ready adjustment of the runner-blade angles to match the opposite requirements of pumping and power generation. The pumping load can also be varied with Deriaz-type units, which cannot be done with a Francis runner. A further advantage of a Deriaz-type machine is that the runner blades can be closed to form a smooth cone, a feature that permits pump start-up with minimum load while the unit is submerged in water.

An early major Deriaz reversible-pump turbine system was installed at plants on both the Canadian and U.S. sides of Niagara Falls; this made it possible to provide “side storage” at night without impairing the tourist attraction of the falls by reducing the flow during the day. The Tuscarora plant on the U.S. side uses 12 pump turbines at heads between 18.3 to 29 metres.

Pumped storage has become widespread in industrialized nations. In the United States alone more than 30 pumped hydropower stations were in operation by the mid-1980s. The largest plant is located in Bath County, Va., where six pump-turbines have a total capacity of 2.1 million kilowatts. This amount of power can be generated over an 11-hour period.

Tidal plants

Although the majority of hydroelectric plants depend on the impoundment of rivers, tidal power still could play a role, albeit minor, in electric power generation during the coming years. Areas where the normal tide runs high, such as in the Bay of Fundy between the United States and Canada or along the English Channel, can allow water to flow into a dam-controlled basin during high tide and discharge it during low tide to produce intermittent power. One such plant is located in France on the estuary of the Rance River near Saint-Malo in Brittany. There, a reservoir has been created by a barrage four kilometres inland from the river mouth to make use of tides ranging from about 3.4 to 13.4 metres. The power station is equipped with 24 reversible bulb-type propeller turbines coupled to reversible motor/generators, each having a capacity of 10,000 kilowatts. Pumped storage is used if the tidal outflow through the plant falls below peak power demands. A pilot tidal plant with a 40,000-kilowatt capacity has been built in Russia on the Barents Sea. If this facility proves economical, it may lead to the construction of other tidal plants on the northern and eastern Russian coasts.

Cost of hydroelectric power

Although large hydroelectric plants can be operated economically, the cost of land acquisition and of dam and reservoir construction must be included in the total cost of power, since these outlays generally account for about half of the total initial cost. Most large plants serve multiple purposes: hydropower generation, flood control, storage of drinking water, and the impounding of water for irrigation. If the construction costs are properly prorated to the non-power-producing utility of the unit, electricity can be sold very cheaply. In the Pacific Northwest region of the United States, such accounting has given hydroelectric plants an apparent cost advantage over fossil-fueled units.

History of water turbine technology

Experiments on the mechanics of reaction wheels conducted by the Swiss mathematician Leonhard Euler and his son Albert in the 1750s found application about 75 years later. In 1826 Jean-Victor Poncelet (Poncelet, Jean-Victor) of France proposed the idea of an inward-flowing radial turbine, the direct precursor of the modern water turbine. This machine had a vertical spindle and a runner with curved blades that was fully enclosed. Water entered radially inward and discharged downward below the spindle.

A similar machine was patented in 1838 by Samuel B. Howd of the United States and built subsequently. Howd's design was improved on by James B. Francis (Francis, James Bicheno), who added stationary guide vanes and shaped the blades so that water could enter shock-free at the correct angle. His runner design, which came to be known as the Francis turbine (see above), is still the most widely used for medium-high heads. Improved control was proposed by James Thomson, a Scottish engineer, who added coupled and pivoted curved guide vanes to assure proper flow directions even at part load.

A radial outward-flow turbine had been proposed in 1824 by the French engineering professor Claude Burdin and his former student Benoît Fourneyron (Fourneyron, Benoît). This device had a vertical axis carrying a runner with curved blades through which the water left almost tangentially. Fixed guide vanes, curved in the opposite direction, were mounted in an annulus inside the runner. Unfortunately the design made it difficult to support the runner and to take power off the turbine wheel. The first successful version of the turbine was built by Fourneyron in 1827. More than 100 such machines were subsequently built all over the world; they achieved efficiencies up to 75 percent at full load with heads up to 107 metres. In 1844 Uriah A. Boyden added an outlet diffuser to recover part of the kinetic energy exiting the device and thereby further improved efficiency. Outward-flow turbines, however, are inherently unstable, and speed control is difficult. Moreover, the construction of outward-flow turbines is very complex as compared to that of Francis-type runners, and this fact led to their eventually being supplanted by the latter.

Francis turbines were augmented by the development of the Pelton wheel (1889) for small flow rates and high heads and by propeller turbines, first built by Kaplan in 1913, for large flows at low heads. Kaplan's variable-pitch propeller turbine, which still bears his name, was manufactured after 1920. These units, together with the Deriaz mixed-flow turbine (invented in 1956), constitute the arsenal of modern water turbines.

By the mid-19th century, water turbines were widely used to drive sawmills and textile mill equipment, often through a complex system of gears, shafts, and pulleys. After the widespread adoption of the steam engine they did not, however, become a major factor in power generation until the advent of the electric generator made hydroelectric power possible.

The world's first hydroelectric central station was built in 1882 in Appleton, Wis., only three years after Thomas Edison's invention of the light bulb. Its output of 12.5 kilowatts was used to light two paper mills and a house. Thereafter hydroelectric power development spread rapidly, though even by 1910 most units delivered only a few hundred to a few thousand kilowatts. Installations with more than 100,000-kilowatt capacity were not built until the 1930s. One of the first large U.S. plants was installed at Hoover Dam on the Colorado River between Nevada and Arizona. It began operating in 1936 and eventually included 17 Francis turbines capable of delivering from 40,000 to 130,000 kilowatts of power, along with two 3,000-kilowatt Pelton wheels.

The first pumped storage plant with a capacity of 1,500 kilowatts was built near Schaffhausen, Switz., in 1909. It made use of a separate pump and turbine, resulting in a relatively large and only barely economical system. The first U.S. plant, built on the Rocky River in Connecticut in 1929, was also only marginally economical. In the United States major work on pumped-storage hydropower began in the mid-1950s, following the success of a plant at Flatiron, Colo. Built in 1954, this facility was equipped with a reversible-pump turbine having a capacity of 9,000 kilowatts.

In highly industrialized countries, such as the United States and the nations of western Europe, most potential sites for hydropower have already been tapped. Environmental concerns relating to the impact of large dams on the upstream watercourse and to the possible effect on aquatic life add to the likelihood that only a few large hydraulic plants will be built in the future.

From about the 1940s to the early 1970s, many small U.S. hydroelectric facilities (primarily those of less than 1,000-kilowatt capacity) were, in fact, closed down because high maintenance and supervision costs made them uneconomical compared to power plants that burn fossil fuels. Even though the increase in fossil-fuel costs since 1973 has led to the rehabilitation of some of these abandoned plants, only a marked increase in fuel prices, coupled with specific needs for irrigation or flood control, is likely to lead to significant new hydroelectric plant construction.

It is estimated that about 75 percent of the potential waterpower in the contiguous United States has already been developed, with the drainage area of the Columbia River in the Pacific Northwest leading in both developed and potential additional power. As of the late 1980s, hydroelectric power met about 13 percent of the total demand for electrical energy in the United States, though this amounts to only 3 percent of the combined U.S. energy usage for mechanical power, heat, light, and refrigeration.

The above considerations do not necessarily apply to such remote areas as Alaska, northern Canada, and Siberia in Russia, or to developing nations in regions of the Himalayas, Africa, and South America. In these areas it is estimated that only 23 percent of the potential waterpower has been developed. For example, less than 1 percent of the estimated 167 million kilowatts available in Alaska has been harnessed to date. Other river basins with large remaining potential capacities include the Fraser River in Canada, the Orinoco in Venezuela, the Brahmaputra in India, and the Yenisey–Angara in Russia. Turbine capacities for some of these remote areas may possibly exceed the current maximum of 740,000 kilowatts per unit.

Steam turbines

A steam turbine consists of a rotor resting on bearings and enclosed in a cylindrical casing. The rotor is turned by steam impinging against attached vanes or blades on which it exerts a force in the tangential direction. Thus a steam turbine could be viewed as a complex series of windmill-like arrangements, all assembled on the same shaft.

Because of its ability to develop tremendous power within a comparatively small space, the steam turbine has superseded all other prime movers, except hydraulic turbines, for generating large amounts of electricity and for providing propulsive power for large, high-speed ships. Today, units capable of generating more than 1.3 million kilowatts of power can be mounted on a single shaft.

Classifications

Large steam turbines are complex machines that can be classified in various ways. One approach centres on whether rotation is achieved by impulse forces or by reaction forces (see below). This distinction may become somewhat blurred, since many modern machines employ a combination of both methods.

Condensing and noncondensing turbines

Steam turbines are often divided into two types: condensing and noncondensing. In devices of the first type, steam is condensed at below atmospheric pressure so as to gain the maximum amount of energy from it. In noncondensing turbines, steam leaves the turbine at above atmospheric pressure and is then used for heating or for other required processes before being returned as water to the boiler. Compared to the fuel needed for simply converting water into steam (saturated steam), relatively little additional fuel has to be expended to increase the steam generator exit pressure and, especially, the temperature in order to produce superheated steam, which then is employed to drive a turbine. Noncondensing turbines are therefore an economical means of generating power (cogeneration) when substantial amounts of heating or process steam are already needed.

In condensing turbines, substantial quantities of cooling water are required to carry away the heat released during condensation. While noncondensing turbines exhaust steam at or above atmospheric pressure, condensing turbines can condense at pressures of 90 to 100 kilopascals (13 to 14.5 pounds per square inch) below atmospheric pressure. This allows for a much larger expansion of the steam and a larger change in enthalpy (see above), resulting in higher work output and greater efficiency. All central station plants, where efficiency is a prime consideration, employ condensing turbines.

Steam extraction

Steam turbines differ according to whether or not a portion of the steam is extracted from intermediate portions of the turbine. Extraction may be carried out to partially reheat the water fed back to the boiler and thereby significantly increase the efficiency of the power plant. In light of this, turbines may be classified as (1) straight-through turbines, in which there is no extraction (or bleeding), (2) bleeder or extraction turbines, and (3) controlled- (or automatic-) extraction turbines.

In bleeder turbines no effort is made to control the pressure of the extracted steam, which varies in almost direct proportion to the load carried by the turbine. Extraction also reduces the steam flow to the condenser, allowing the turbine exhaust area to be reduced. Controlled-extraction turbines are designed for withdrawing variable amounts of constant-pressure steam irrespective of the load on the turbine. They are frequently selected for industrial use when steam at fixed intermediate pressures is demanded by process operations. Since both extraction pressures and turbine speed should be kept constant, a complex system is required for controlling steam flow, which increases the cost. Controlled-extraction turbines may be designed for both condensing and noncondensing operations.

Reheat and nonreheat turbines

If high-pressure, high-temperature steam is partially expanded through a turbine, the efficiency can be increased by returning the steam to the steam generator and reheating it to approximately its original temperature before feeding it back to the turbine. Single reheat turbines are common in the electric utility industry. For very large units, double reheating may be employed. Nonreheat turbines are currently limited mostly to industrial plants and small utilities.

Multiflow and compound arrangements

Steam entering a turbine at a high pressure and temperature—say, 24,100 kilopascals gauge, or 3,500 pounds per square inch gauge (where gauge denotes pressure above atmospheric value), and 600° C—can have a volume increase of more than a thousandfold if it is expanded to below atmospheric condenser pressures. To keep the steam velocity through the turbine essentially constant, the annular flow area would have to increase more than a thousandfold, necessitating very large diameter casings and excessively long turbine blades near the exit. In large turbines this problem is alleviated by splitting the low-pressure stream into a number of parallel flow sections.

This flow splitting also leads to another method of classification that differentiates between having the whole machine assembled along a single shaft with one generator (tandem-compound turbines) or utilizing two shafts, each with its own generator (cross-compound turbines).

Principal components

The main parts of a steam turbine are (1) the rotor that carries the blading to convert the thermal energy of the steam into the rotary motion of the shaft, (2) the casing, inside of which the rotor turns, that serves as a pressure vessel for containing the steam (it also accommodates fixed nozzle passages or stator vanes through which the steam is accelerated before being directed against and through the rotor blading), (3) the speed-regulating mechanism, and (4) the support system, which includes the lubrication system for the bearings that support the rotor and also absorb any end thrust developed.

Design considerations

Blading design

The turbine blading must be carefully designed with the correct aerodynamic shape to properly turn the flowing steam and generate rotational energy efficiently. The blades also have to be strong enough to withstand high centrifugal stresses and must be sized to avoid dangerous vibrations. Various types of blading arrangements have been proposed, but all are designed to take advantage of the principle that when a given mass of steam suddenly changes its velocity, a force is then exerted by the mass in direct proportion to the rate of change of velocity.

Two types of blading have been developed to a high degree of perfection: impulse blading and reaction blading. The principle of impulse blading is illustrated in the schematic diagram of Figure 1-->

Two types of blading have been developed to a high degree of perfection: impulse blading and reaction blading. The principle of impulse blading is illustrated in the schematic diagram of Figure 1--> for a first stage. A series of stationary nozzles allows the steam to expand to a lower pressure while its velocity and kinetic energy increase. The steam is then directed to the moving passages or buckets where the kinetic energy is extracted. Since there is ideally no pressure drop and no acceleration in the blade passage, the magnitude of the velocity vector in the blades should remain constant. This also implies that the cross-sectional area normal to the flow remains constant, giving rise to the typical shape of a symmetrical impulse blade—namely, thick at the middle and sharp at the ends.

for a first stage. A series of stationary nozzles allows the steam to expand to a lower pressure while its velocity and kinetic energy increase. The steam is then directed to the moving passages or buckets where the kinetic energy is extracted. Since there is ideally no pressure drop and no acceleration in the blade passage, the magnitude of the velocity vector in the blades should remain constant. This also implies that the cross-sectional area normal to the flow remains constant, giving rise to the typical shape of a symmetrical impulse blade—namely, thick at the middle and sharp at the ends. Figure 1-->

Figure 1--> also includes the velocity diagrams for such a stage. Velocities are vectors that are added by the parallelogram law. The relative velocity of the fluid with reference to the blade at inlet (or exit) added vectorially to the (tangential) velocity of the blade must give the absolute velocity as seen by the stationary passages. That the kinetic energy at the nozzle exit (proportional to the square of the nozzle-leaving velocity) is much larger than that at the blade exit is apparent from the figure. In an ideal impulse stage, this change of kinetic energy is fully converted into useful work. For minimum exit kinetic energy in a symmetrical impulse blade, the rotor velocity should be about one-half of the entering steam velocity.

also includes the velocity diagrams for such a stage. Velocities are vectors that are added by the parallelogram law. The relative velocity of the fluid with reference to the blade at inlet (or exit) added vectorially to the (tangential) velocity of the blade must give the absolute velocity as seen by the stationary passages. That the kinetic energy at the nozzle exit (proportional to the square of the nozzle-leaving velocity) is much larger than that at the blade exit is apparent from the figure. In an ideal impulse stage, this change of kinetic energy is fully converted into useful work. For minimum exit kinetic energy in a symmetrical impulse blade, the rotor velocity should be about one-half of the entering steam velocity. In an idealized reaction stage, about one-half of the enthalpy drop per stage is effected in the stator passage and the other half in the rotor passage. This implies that the pressure drop is also almost equal in both the stationary and the rotary passages, which tend to look like mirror images of each other. If the flow velocity is subsonic (below the velocity of sound in the fluid), an expanding passage flow will increase its velocity as the pressure drops while the cross-sectional area decreases simultaneously, thus leading to the curved nozzle shape shown in Figure 2-->

In an idealized reaction stage, about one-half of the enthalpy drop per stage is effected in the stator passage and the other half in the rotor passage. This implies that the pressure drop is also almost equal in both the stationary and the rotary passages, which tend to look like mirror images of each other. If the flow velocity is subsonic (below the velocity of sound in the fluid), an expanding passage flow will increase its velocity as the pressure drops while the cross-sectional area decreases simultaneously, thus leading to the curved nozzle shape shown in Figure 2--> .

.Since there is no pressure drop in an idealized impulse stage, pressure forces on the rotor play no role in this type of arrangement. By contrast, in a reaction stage, the effect of the changing pressure exerts a net force in the tangential direction (thus turning the wheel) and also in the axial direction. The latter tends to push the rotor into the ends of the casing, requiring a thrust bearing to absorb the axial load. In large turbines the axial load can be reduced by admitting the steam flow in the middle and expanding in both axial directions.

There is no need to match the increase of fluid velocity in the stator to that in the rotor (50 percent reaction). Other widely used combinations that fall between pure impulse and 50 percent reaction staging have been developed.

The large length of low-pressure blades imposes special requirements on stiffness in addition to aerodynamic shaping. The tangential velocity of the blade near the hub is much smaller than at the blade tip, while the axial through-flow velocity is maintained nearly constant. To match the flow, the blades must be twisted to have the correct approach angle for the incoming steam and at the same time avoid possible resonant vibrations.

Turbine staging

Only a small fraction of the overall pressure drop available in a turbine can be extracted in a single stage consisting of a set of stationary nozzles or vanes and moving blades or buckets. In contrast to water turbines where the total head is extracted in a single runner (see above), the steam velocities obtained from the enthalpy drop between steam generator and condenser would be prohibitively high. In addition, the volume increase of the expanding steam requires a large increase in the annular flow area to keep the axial through-flow velocity nearly constant. To this must be added limitations on blade length and blade-tip velocities to avoid excessive centrifugal stresses. In practice, the steam expansion is therefore broken up into many small segments or stages, each with a range of velocities and an appropriate blade size to permit efficient conversion of the thermal energy in the steam to mechanical energy. In modern turbines, three types of staging are employed, either separately or in combination: (1) pressure (or impulse) staging, (2) reaction staging, and (3) velocity-compound staging.

Pressure staging uses a number of sequential impulse stages similar to those illustrated in Figure 1-->

Pressure staging uses a number of sequential impulse stages similar to those illustrated in Figure 1--> , except that the stationary passages also become highly curved nozzles. Pressure-staged turbines can range in power capacity from a few to more than 1.3 million kilowatts. Some manufacturers prefer to build units with impulse stages simply to reduce thrust-bearing loads. Such units may have as many as 20 sequential stages.

, except that the stationary passages also become highly curved nozzles. Pressure-staged turbines can range in power capacity from a few to more than 1.3 million kilowatts. Some manufacturers prefer to build units with impulse stages simply to reduce thrust-bearing loads. Such units may have as many as 20 sequential stages.Reaction staging is similar to pressure staging, except that a greater number of reaction stages are required. The first turbine stage, however, is often an impulse stage for controlling the steam flow and for rapidly reducing the pressure in stationary nozzles from its high steam generator value, thereby lowering the pressure that the casing has to withstand. Reaction turbines require about twice as many stages as impulse-staged turbines for the same change in steam enthalpy. The cost and size of the turbines, however, are about the same because blading for pressure staging must withstand greater forces and must therefore be more rigidly constructed. Reaction turbines also have large axial thrust and require heavy-duty thrust bearings.

In velocity-compound staging a set of stationary nozzles is followed by two sets of moving blades with a stationary row of impulse blades between them to redirect the flow. Ideally this allows twice as much power to be extracted than from a single impulse stage for a given blade-tip velocity. It also permits a large pressure drop through the stationary nozzles. Velocity-compounding is well suited for small turbines; it is also sometimes used as the first stage in large turbines for control purposes. The inherent high steam velocities, however, tend to result in high losses and poor stage efficiencies.

power development

The theoretical maximum power produced by a turbine can be computed from the mass flow rate of the steam multiplied by the ideal enthalpy drop per unit mass between the steam generator exit and the condenser conditions. The actual power produced, however, is less because of friction, turbulence, leakage around the blade tips, and other losses. For the same maximum blade-tip velocity, pressure staging produces about twice as much ideal power per stage as reaction staging, while velocity-compound staging produces about four times as much.

The stage efficiency—i.e., the amount of work that is actually produced in each stage as compared to the maximum possible amount—can be higher for reaction stages than for impulse stages due to generally lower flow velocities and associated losses. The greater number of stages required, however, results in an overall turbine efficiency that is about the same for both. Efficient stages also require carefully designed seals along the rotor shaft and opposite the rotating blade tips to avoid leakage past the blades.

Control (control system)

A turbine driving an electric generator must run at constant speed. In the United States where 60-cycle-per-second alternating current is used, this usually means 3,600 or 1,800 revolutions per minute. (In countries that use 50-cycle current, 3,000 or 1,500 revolutions per minute are the norm.) When the electric power demand on the generator, or the load, changes, the turbine must respond immediately to keep the speed constant. The inlet enthalpy is determined by the exit conditions of the steam generator and the exit enthalpy by the condenser pressure. Neither of these can be varied rapidly. With a fixed enthalpy drop per unit mass, the power output thus can only be controlled by varying the mass flow rate. This is achieved by opening or closing valves leading to the turbine inlet stage. Under partial load, the reduced steam flow results in lower axial velocities along the turbine and thereby alters the velocity diagrams somewhat. Since efficient operation requires a careful match between all velocity directions and blade inlet shapes, part-load operation decreases the efficiency of the turbine.

Overall performance characteristics

The performance of a steam turbine is conventionally measured in terms of its heat rate—i.e., the amount of heat that has to be supplied to the feedwater in order to produce a specified generator power output. In the United States the heat rate is given by the heat input in Btus per hour for each kilowatt-hour of electricity produced by the turbogenerator assembly. The heat rate depends on the steam generator exit temperature and pressure, the condenser pressure, the efficiency of the turbine in converting the thermal energy of the steam into work, the mechanical and bearing losses, the exhaust loss due to the kinetic energy of the steam leaving the final turbine stage, and the generator losses. The lower the heat rate, the less the thermal energy required and the better the efficiency. At constant condenser pressure, the heat rate can be decreased by about 11 percent when going from steam generator exit conditions of 10,000 kilopascals gauge and 538° C to 24,100 kilopascals gauge and 538° C, with a subsequent reheat temperature of 538° C. The higher pressure, however, necessitates costlier equipment to contain the steam and to maintain the same reliability. Part-load operation, with its attendant loss of efficiency, always leads to higher heat rates.

History of steam turbine technology

Early precursors

The first device that can be classified as a reaction steam turbine is the aeolipile proposed by Hero of Alexandria, during the 1st century AD. In this device, steam was supplied through a hollow rotating shaft to a hollow rotating sphere. It then emerged through two opposing curved tubes, just as water issues from a rotating lawn sprinkler. The device was little more than a toy, since no useful work was produced.

Another steam-driven machine, described in 1629 in Italy, was designed in such a way that a jet of steam impinged on blades extending from a wheel and caused it to rotate by the impulse principle. Starting with a 1784 patent by James Watt, the developer of the steam engine, a number of reaction and impulse turbines were proposed, all adaptations of similar devices that operated with water. None were successful except for the units built by William Avery of the United States after 1837. In one such Avery turbine two hollow arms, about 75 centimetres long, were attached at right angles to a hollow shaft through which steam was supplied. Nozzles at the outer end of the arms allowed the steam to escape in a tangential direction, thus producing the reaction to turn the wheel. About 50 of these turbines were built for sawmills, cotton gins, and woodworking shops, and at least one was tried on a locomotive. While the efficiencies matched those of contemporary steam engines, high noise levels, difficult speed regulation, and frequent need for repairs led to their abandonment.

Development of modern steam turbines

No further developments occurred until the end of the 19th century when various inventors laid the groundwork for the modern steam turbine. In 1884 Sir Charles Algernon Parsons (Parsons, Sir Charles Algernon), a British engineer, recognized the advantage of employing a large number of stages in series, allowing extraction of the thermal energy in the steam in small steps. Parsons also developed the reaction-stage principle according to which a nearly equal pressure drop and energy release takes place in both the stationary and moving blade passages. In addition, he subsequently built the first practical large marine steam turbines. During the 1880s Carl G.P. de Laval (Laval, Carl Gustaf Patrik de) of Sweden constructed small reaction turbines that turned at about 40,000 revolutions per minute to drive cream separators. Their high speed, however, made them unsuitable for other commercial applications. De Laval then turned his attention to single-stage impulse turbines that used convergent-divergent nozzles, such as the one shown in Figure 3-->

No further developments occurred until the end of the 19th century when various inventors laid the groundwork for the modern steam turbine. In 1884 Sir Charles Algernon Parsons (Parsons, Sir Charles Algernon), a British engineer, recognized the advantage of employing a large number of stages in series, allowing extraction of the thermal energy in the steam in small steps. Parsons also developed the reaction-stage principle according to which a nearly equal pressure drop and energy release takes place in both the stationary and moving blade passages. In addition, he subsequently built the first practical large marine steam turbines. During the 1880s Carl G.P. de Laval (Laval, Carl Gustaf Patrik de) of Sweden constructed small reaction turbines that turned at about 40,000 revolutions per minute to drive cream separators. Their high speed, however, made them unsuitable for other commercial applications. De Laval then turned his attention to single-stage impulse turbines that used convergent-divergent nozzles, such as the one shown in Figure 3--> . From 1889 to 1897 de Laval built many turbines with capacities from about 15 to several hundred horsepower. His 15-horsepower turbines were the first employed for marine propulsion (1892). C.E.A. Rateau of France first developed multistage impulse turbines during the 1890s. At about the same time, Charles G. Curtis of the United States developed the velocity-compounded impulse stage.

. From 1889 to 1897 de Laval built many turbines with capacities from about 15 to several hundred horsepower. His 15-horsepower turbines were the first employed for marine propulsion (1892). C.E.A. Rateau of France first developed multistage impulse turbines during the 1890s. At about the same time, Charles G. Curtis of the United States developed the velocity-compounded impulse stage.By 1900 the largest steam turbine-generator unit produced 1,200 kilowatts, and 10 years later the capacity of such machines had increased to more than 30,000 kilowatts. This far exceeded the output of even the largest steam engines, making steam turbines the principal prime movers in central power stations after the first decade of the 20th century. Following the successful installation of a series of 68,000-horsepower turbines in the transatlantic passenger liners Lusitania and Mauretania, launched in 1906, steam turbines also gained preeminence in large-scale marine applications, first with vessels burning fossil fuels and then with those using nuclear power. Steam generator pressures increased from about 1,000 kilopascals gauge in 1895 to 1,380 kilopascals gauge by 1919 and then to 9,300 kilopascals gauge by 1940. Steam temperatures climbed from about 180° C (saturated steam) to 315° C (superheated steam) and eventually to 510° C over the same time period, while heat rates decreased from about 38,000 to below 10,000 Btus per kilowatt-hour.

Recent developments and trends

By 1940, single turbine units with a power capacity of 100,000 kilowatts were common. Ever-larger turbines (with higher efficiencies) have been constructed during the last half of the century, largely because of the steadily rising cost of fossil fuels. This required a substantial increase in steam generator pressures and temperatures. Some units operating with supercritical steam at pressures as high as 34,500 kilopascals gauge and at temperatures of up to 650° C were built before 1970. Reheat turbines that operate at lower pressures (between 17,100 to 24,100 kilopascals gauge) and temperatures (540–565° C) are now commonly installed to assure high reliability. Steam turbines in nuclear power plants, which are still being constructed in a number of countries outside of the United States, typically operate at about 7,580 kilopascals gauge and at temperatures of up to 295° C to accommodate the limitations of reactors. Turbines that exceed one-million-kilowatt output require exceptionally large, highly alloyed steel blades at the low pressure end.

Slightly more efficient units with a power capacity of more than 1.3 million kilowatts may eventually be built, but no major improvements are expected within the next few decades, primarily because of the temperature limitations of the materials employed in steam generators, piping, and high-pressure turbine components and because of the need for very high reliability.

Although the use of large steam turbines is tied to electric power production and marine propulsion, smaller units may be used for cogeneration when steam is required for other purposes, such as for chemical processing, powering other machines (e.g., compressors of large central air-conditioning systems serving many buildings), or driving large pumps and fans in power stations or refineries. However, the need for a complete steam plant, including steam generators, pumps, and accessories, does not make the steam turbine an attractive power device for small installations.

Wind turbines

Modern wind turbines extract energy from the wind, mostly for electricity generation (electric power), by rotation of a propeller-like set of blades that drive a generator through appropriate shafts and gears. The older term windmill is often still used to describe this type of device, although electric power generation rather than milling has become the primary application. As was noted earlier, windmills, together with waterwheels, were widely used from the Middle Ages to the 19th century during the course of which they were supplanted by steam engines and steam turbines. Though they continued to be used for pumping water in rural areas, wind turbines practically disappeared in the 20th century as the internal-combustion engine and electricity provided more reliable and usually less expensive power. Interest in wind turbines for electricity generation was rekindled by the oil crisis of the mid-1970s. High initial costs, intermittent operation, and maintenance costs, however, have prevented wind turbines from becoming a significant factor in commercial power production.

Modern wind turbines extract energy from the wind, mostly for electricity generation (electric power), by rotation of a propeller-like set of blades that drive a generator through appropriate shafts and gears. The older term windmill is often still used to describe this type of device, although electric power generation rather than milling has become the primary application. As was noted earlier, windmills, together with waterwheels, were widely used from the Middle Ages to the 19th century during the course of which they were supplanted by steam engines and steam turbines. Though they continued to be used for pumping water in rural areas, wind turbines practically disappeared in the 20th century as the internal-combustion engine and electricity provided more reliable and usually less expensive power. Interest in wind turbines for electricity generation was rekindled by the oil crisis of the mid-1970s. High initial costs, intermittent operation, and maintenance costs, however, have prevented wind turbines from becoming a significant factor in commercial power production.Types of wind turbines

Horizontal axis machines

The best-known machines of this type are the so-called American farm windmills that came into wide use during the 1890s. Such devices consist of a rotor, which may have up to 20 essentially flat sheet-metal blades and a tail vane that keeps the rotor facing into the wind by swiveling the entire rotor assembly. Governing is automatic and overspeeding is avoided by turning the wheel off the wind direction, thus reducing the effective sail area while keeping the speed constant. A typical pump can deliver about 38 litres (10 gallons) per minute to a height of 30 metres at a wind velocity of 6.7 metres per second (15 miles per hour).

Modern wind turbines have from one to four metal blades that operate at much higher rotor-tip speeds than windmills. Each blade is twisted like an airplane propeller. An automatic governor rotates the blades about their support axis to maintain constant generator speed. The Jacobs three-bladed windmill, used widely between 1930 and 1960, could deliver about one kilowatt of power at a wind speed of 6.25 metres per second, a typical average wind velocity in the United States about 18 metres above ground.

More recently, large horizontal-shaft, two-bladed turbines have been developed in the United States. The first such device, a unit equipped with a rotor measuring 11.6 metres in diameter, was installed near Sandusky, Ohio, in 1976; its power output was rated at 100 kilowatts. The most recent type of machine, first installed on the island of Oahu in Hawaii, has a rotor diameter of 122 metres with its axis about 76 metres above ground. Its output rating is 6,200 kilowatts at a wind speed of 13 metres per second.

Vertical-axis machines

Devices of this kind, which had not been used since the early Middle Ages, found a new application after the Finnish engineer S.J. Savonius invented a new type of rotor in 1922. Known as the Savonius rotor, it consists of semicircular blades that can be constructed from little more than the two sections of an oil drum, cut in half along its vertical axis and welded together with an offset from the axis to form an open S (see photograph-->

Devices of this kind, which had not been used since the early Middle Ages, found a new application after the Finnish engineer S.J. Savonius invented a new type of rotor in 1922. Known as the Savonius rotor, it consists of semicircular blades that can be constructed from little more than the two sections of an oil drum, cut in half along its vertical axis and welded together with an offset from the axis to form an open S (see photograph--> ). An advanced version of this machine installed at Manhattan, Kan., during the 1970s generated five kilowatts of electric power in a 12-metre-per-second wind.

). An advanced version of this machine installed at Manhattan, Kan., during the 1970s generated five kilowatts of electric power in a 12-metre-per-second wind. The most recent vertical wind turbine is based on a machine patented in 1931 by the French engineer G.J.M. Darrieus. Its two blades consist of twisted metal strips tied to the shaft at the top and bottom and bowed out in the middle similar to the blades on a food mixer. A Darrieus turbine with aluminum blades erected in 1980 by the Sandia National Laboratories in New Mexico produced 60 kilowatts in a wind blowing 12.5 metres per second. Turbines of this variety are not self-starting and require an external motor for start-up. Several models of Darrieus turbines have been built since the construction of the Sandia unit (see photograph-->

The most recent vertical wind turbine is based on a machine patented in 1931 by the French engineer G.J.M. Darrieus. Its two blades consist of twisted metal strips tied to the shaft at the top and bottom and bowed out in the middle similar to the blades on a food mixer. A Darrieus turbine with aluminum blades erected in 1980 by the Sandia National Laboratories in New Mexico produced 60 kilowatts in a wind blowing 12.5 metres per second. Turbines of this variety are not self-starting and require an external motor for start-up. Several models of Darrieus turbines have been built since the construction of the Sandia unit (see photograph--> ).

).Wind farms

A wind farm is a cluster of wind turbines (up to several hundred) erected in areas where there is a nearly steady prevalent wind; such areas generally occur near mountain passes. Wind farms comprising propeller-type units have been set up in Hawaii, California, and New Hampshire. Capacities range from 10 to 500 kilowatts per unit. During 1984 the total output of all U.S. wind farms exceeded 150 million kilowatt-hours; the entire output was fed into the electric utility network. Though seemingly substantial, this amounted to less than 1/100,000 of the total electric power generated in the United States.

Limitations on wind power

Not all the kinetic energy of the wind can be extracted, because there must be a finite velocity as the air leaves the blading. It can be shown that the maximum efficiency (energy extracted divided by energy available in the captured wind area) obtainable is about 59 percent, although actual wind turbines extract only a portion of this amount. Currently, the maximum efficiency obtainable with a propeller-type windmill is roughly 47 percent; this occurs when the propeller-tip speed is between five and six times the wind velocity. For a given rotor speed, it drops rapidly as the wind velocity decreases. The power obtainable varies as the square of the rotor diameter and the cube of the wind velocity. Thus the theoretical maximum energy obtainable from a rotor with a diameter of 30 metres in a wind with a speed of 14 metres per second would be about 690 kilowatts. If the wind speed decreases to 7 metres per second, the theoretical maximum drops to about 86 kilowatts. At this lower wind speed, it would require more than 17,000 wind turbines (with rotors of 30 metres across) operating at an efficiency of 40 percent to match the output of a single large one-million-kilowatt central power station. When these limitations are coupled to the need for suitable sites with steady winds, it becomes apparent that wind turbines alone will not play a major role in meeting the power demands of an industrialized nation.

Development of wind turbines

The emergence and evolution of wind-driven devices for electric power generation are briefly surveyed here. For the origin and development of the traditional windmill and other predecessors of modern wind turbines, see the article energy conversion.

The development of the electric generator aroused some interest in the wind as a “free” power source. The first windmill to drive a generator was built in 1890 by P. LaCour in Denmark, using patent sails and twin fantails on a steel tower.

Adopting the ideas gained from airfoil and aircraft propeller designs, windmill designers and manufacturers began to replace broad windmill sails with a few slender propeller-like blades. In 1931 the first propeller wind turbine was erected in the Crimea. From the 1940s, experimental twin-blade turbines were constructed in the United States and later in Scotland and France. In The Netherlands a few old-fashioned mills were adapted to generate electricity. Today, wind turbines for electric power generation are most commonly propeller-type machines.

Additional Reading

General principles are considered in Aubrey F. Burstall, A History of Mechanical Engineering (1963); G.T. Csanady, Theory of Turbomachines (1964); and Calvin Victor Davis and Kenneth E. Sorensen (eds.), Handbook of Applied Hydraulics, 3rd ed. (1969, reprinted 1984). Discussions of steam and wind turbines are provided by W.G. Steltz and A.M. Donaldson (eds.), Aero-thermodynamics of steam turbines (1981); and Gary L. Johnson, Wind Energy Systems (1985).

- Babson College

- Baburen, Dirck van

- Babuyan Islands

- Baby Dodds

- Baby Face Nelson

- Babylon

- Babylonia

- Babylonian calendar

- Babylonian Exile

- Babylonian Talmud

- baby's breath

- Baby Yar

- Bacab

- Bacall, Lauren

- Bacan

- baccarat

- Baccarat glass

- Bacchanalia

- Bacchelli, Riccardo

- Bacchus Marsh

- Bacchylides

- Baccio Bandinelli

- Baccio d'Agnolo

- Bach, Carl Philipp Emanuel

- Bachchan, Amitabh